Onsite grinding and surface finishing on:

Dryer section ¦ Drums ¦ Calander rolls ¦ Press section ¦ Yankee cylinders

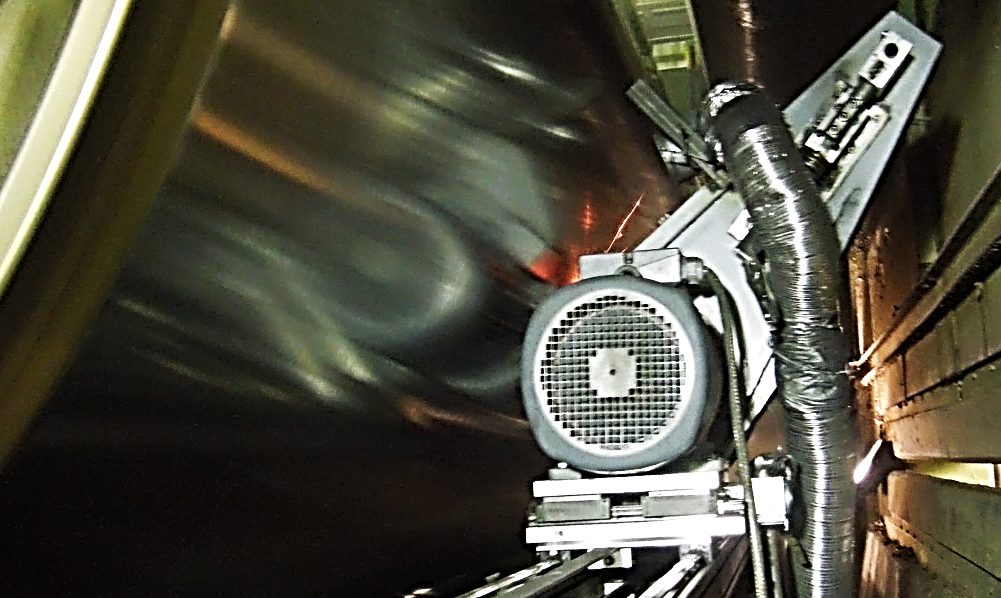

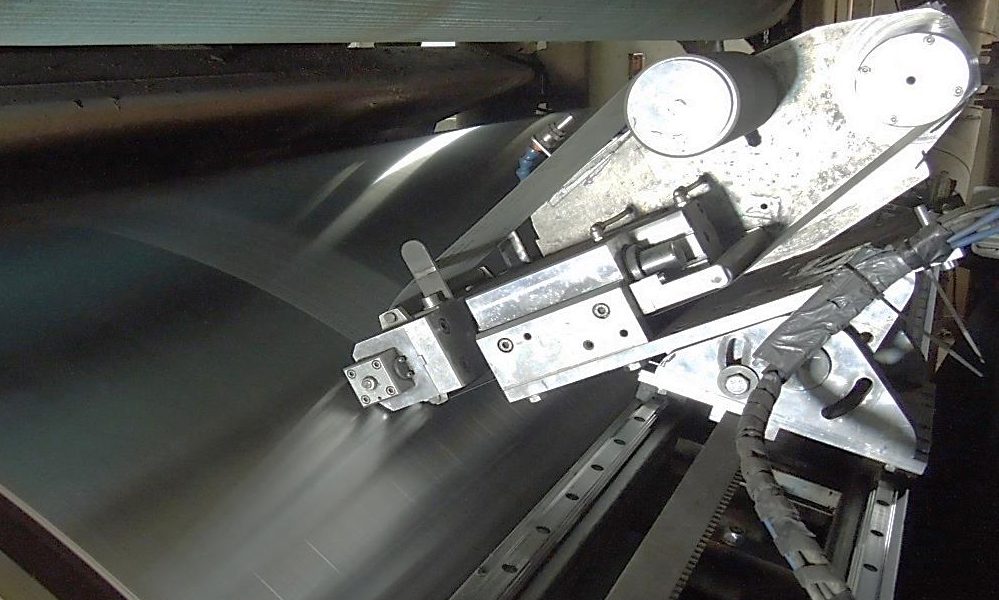

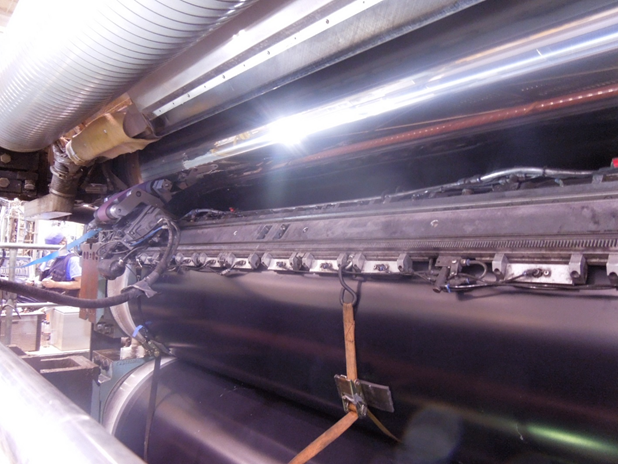

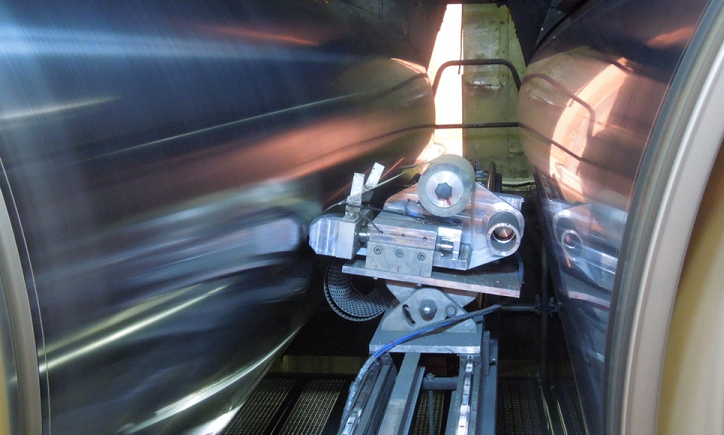

Dryer section

Conventional belt grinding

- Improved runability, heat transfer and moisture profile of paper.

- Repairing of cylinder geometry errors like;

- Roundness, diameter variation

- Removing of damage

- Doctor blade scatter marks, dents and rust

Finishing of dryers

- Material removal up to 0,3mm on diameter

- Repairing of minor axial diameter variation errors

- Removing of dirt and rust

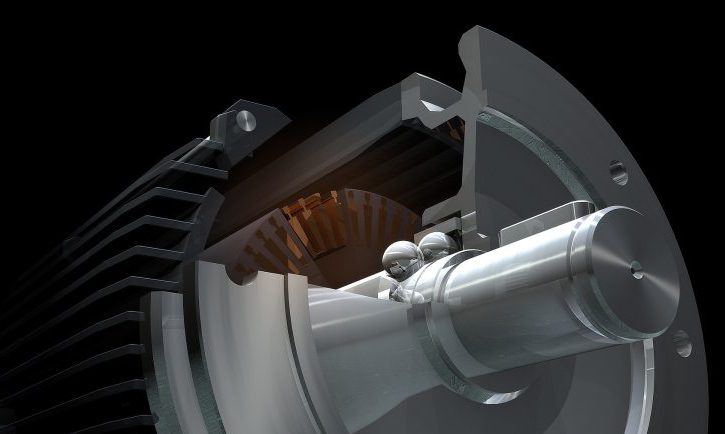

Calander rolls and press section

Press section

- Surface finishing of ceramic center rolls on-site.

- Trough our on-site finishing service the wanted Ra-value of press section rolls can be restored and a smooth release of paper is ensured.

- We do have experience of the ceramic cover finishing of the biggest cover manufacturers.

Calander rolls

- Quick and almost dustless operation to achieve perfect gloss and calandering properties on-site.

-

For both soft and hard covers, for example tungsten carbide and different composites.

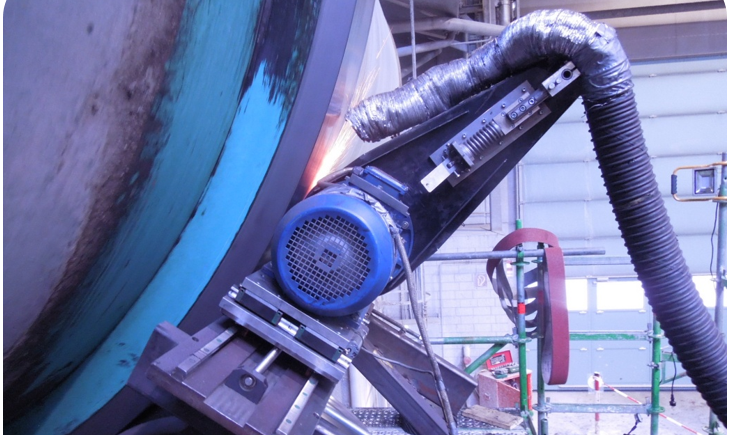

Drums

Support roll grinding

Support ring grinding

Barker Drum Grinding

- Repairing of drum carrier surfaces with grinding of support rolls and rings, both axial and radial support surfaces.

- We understand the behaviour of both rigid and floating rings and have a method to make a successful service grinding.

- Vibration measurements before and after work if needed.

- Wintech can arrange a temporiraly drive for the drums, if needed

Furthermore onsite service offering:

Machining

-

Different on-site machining services, like on-site drilling, turning and grooving.

Onsite Balancing in 2 planes

-

On-site balancing and vibration analysis of rotary machine components, for example cylinders, blowers and rolls.

Engineering

- 3d-modelling and machine design (Solidworks)

- Troubleshooting of paper making processes and start up service of new machinery, especially SYM-rolls.